How to Connect IoT Sensor to IoT Gateway and Optimization Methods

- Richard Wang

- January 11, 2025

- 2:43 pm

Preface

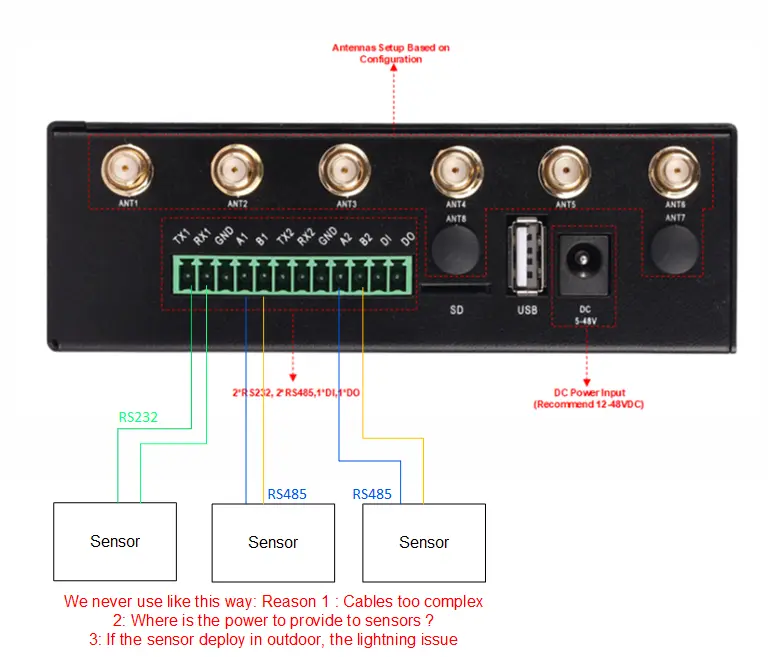

A general IoT solution includes an IoT sensor and an IoT gateway. Many customers choose to directly connect the IoT sensor to the RS232 or RS485 interface of the IoT gateway during deployment. This common practice will face many problems when an IoT gateway needs to connect multiple IoT sensors and the deployment scenario is outdoors. This article attempts to discuss how to optimize the connection between multiple IoT sensors and IoT gateways.

Table of Contents

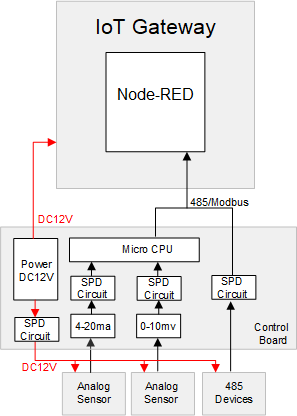

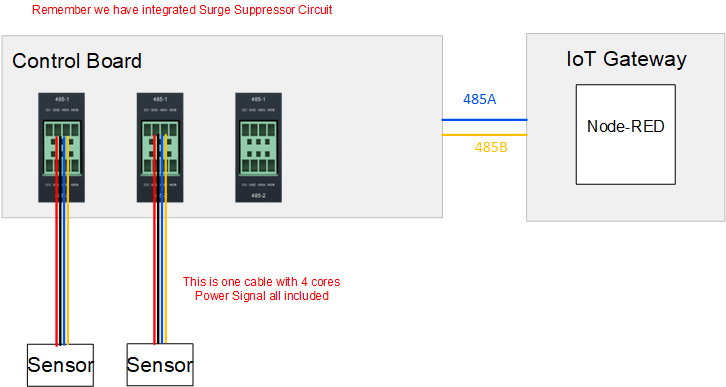

1.Typical Topology of IoT Sensor Connected to IoT Gateway

The above figure is a simplified topology. The IoT sensor is connected to the IoT gateway, and the IoT gateway processes the information it reads locally and reports it to the IoT application. From this simple topology, we can understand that the IoT sensor will be directly connected to the IoT gateway. However, in actual scenarios, it is not that simple. The main problems are as follows:

- When there are many IoT sensors to be connected to the IoT gateway, the connection will be very complicated

- The interface and protocol of the IoT sensor will be more variable, but the IoT gateway cannot cope with such a variable scenario with a standard product form.

- The power supply voltage of the IoT sensor may be different, and the power supply line is more difficult to manage when there are a large number of IoT sensors.

- If the IoT sensor is deployed outdoors, the lightning protection design must be considered. In this way, the deployment of SPD will make the cable connecting the IoT sensor to the IoT gateway more complicated.

Based on the above reasons, Edgeware believes that the design here can be optimized to a certain extent.

2.Weakness of Typical Topology of IoT Sensor Connected to IoT Gateway

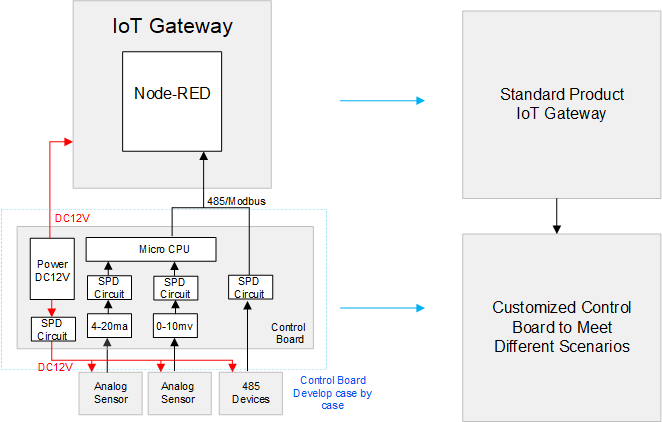

The above diagram shows a general understanding of how to integrate an IoT sensor using an IoT router, however we don’t typically deploy it this way as there are several key issues with this deployment.

- Cable is too complex

Imagine if we have a sensor to be integrated into the EX900, there may be six cables (RS232 has TX and RX, RS485 has A and B) these cables are staggered together in the deployment will be more troublesome, and the deployment of a long time maintenance is also troublesome. Deployment time engineers should pay close attention to whether the cable is connected to the right and so on. Although for experienced engineers is not difficult, but we have to consider not all sites in the city, if deployed in remote areas that means we need to send experienced engineers to deploy there, the overall cost is higher.

- Power Providing for Sensors

If we follow the above diagram, we need to consider the problem of providing power for the sensors separately. With three sensors, there are three more cables, plus the signal cable, that’s nine cables.

And there is another situation, if some sensors require DC24V, some require DC12V, then you need to consider different power supply.

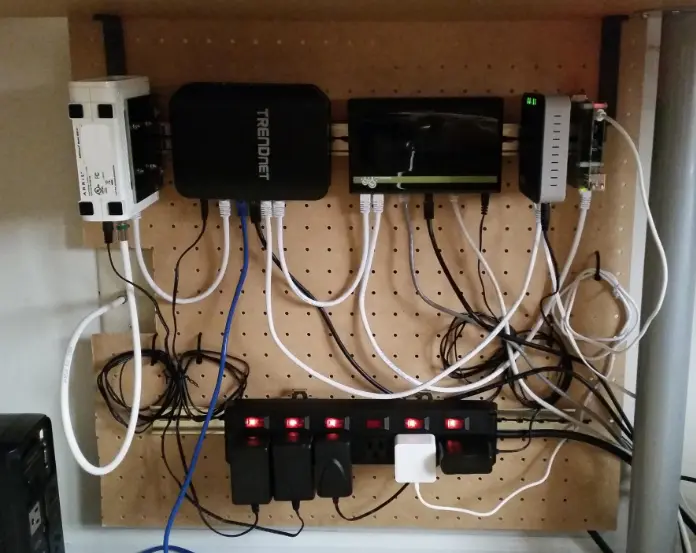

Then it is likely that your deployment will become the above this way, this is a typical thinking, but we do not think it is necessary. This is a typical thinking, but we do not think it is necessary to do so. This deployment is complex, and follow-up maintenance engineers are not easy to maintain. In addition, as we said, you can not guarantee that the site are in very close proximity. Assuming the site is in a rural area, this deployment model you have to send engineers there, which is very expensive.

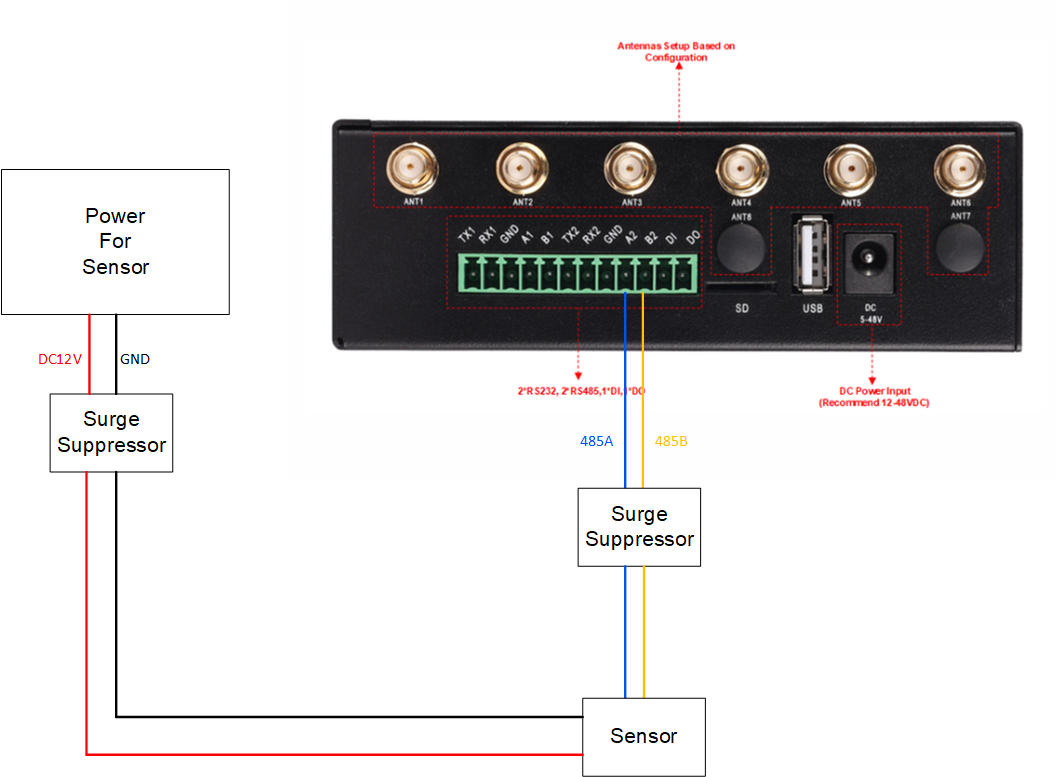

- Lightning Protection

If the IoT sensor is deployed in outdoor, it is better to add surge suppressor to both the signal line from the IoT sensor to IoT gateway and the power line to supply power to the sensor, otherwise the probability of equipment damage due to lightning problems will affect the availability of the system. Many customers will ignore this piece, but this piece is very important.

The main reason for the industry to deploy in the above way is that Industrial router or IoT router does not have the ability to develop and understand the whole scenario, they just want to sell a standard box, and the scenario and the periphery are all handed over to the customer to solve. This brings a lot of extra work and trouble to customer deployment.

3.Optimization of Connection Between IoT Sensor to IoT Gateway

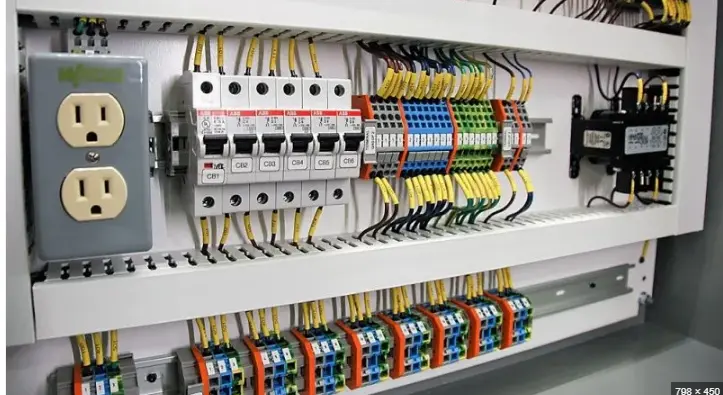

Our proposed architecture is generally like this, we will customize some expansion boards for our customers according to the scenario case by case. Then these expansion boards will take the following factors into consideration.

- lightning protection design

Edgeware places a high priority on lightning protection because we have deployed in the Caribbean region of Central America in the Western Hemisphere. Those regions have more thunderstorms, if the lightning protection design once there is a problem, will be exposed. In the Asian region we found that many customers do not pay attention to, in fact, this is very important. Because we have to consider a lot of sites are in remote areas, if there is a problem to the station maintenance and replacement of spare parts and other costs are very high. Sometimes the cost is much higher than the equipment itself.

Our experience is that whether it is a signal port or a power port, as long as there is a cable through the outdoor must consider the lightning protection design. Therefore, we usually design SPD protection circuits for 4-20ma signals, 485 signals or power supply outputs on the control board.

- Extension and conversion to 485/Modbus for some protocols not included in the IoT Gateway

When the interface is not enough or the interface type is diverse, the general manufacturers will consider the above model. Will be able to think of a variety of interfaces are put on the device. This way to increase the cost at the same time, the actual use will be very troublesome. Because you can consider how many cables will come out of this device. At the same time the most trouble is that, in fact, IoT integration or IoT scene is very diverse, it is impossible to expect a device to cover all the scenes. Why is the mainstream product on the market in the form of the above picture? Because most of the manufacturers are limited by their ability, they don’t want to touch the whole scenario, and at the same time maximize the standardization of their products, leaving the trouble to the customers. Edgeware’s concept is as follows:

Edgeware believes that it is not possible to have one device to cover all scenarios, so standard product and customized scenario have to be decoupled. We use IoT gatewway as a standard product, while the customized scenario is extended by a specially developed control board. At the same time, we use Node-red program to absorb the customized content. For example, the 4-20ma and 0-10mv you mentioned can be extended in this way. The price for us to design this control board for our customers will not be very expensive, we mainly consider how to help our customers better deployment, because you are more convenient to deploy we also invest less resources to help debug, we are all favorable.

- Sensor powered design

When the Sensor many times, we think that their power supply can be completely by our design of the control board to supply, which on the one hand makes the deployment of the power design of the simplification, on the other hand, we will consider the power supply to the Sensor if the outdoor lightning protection design, so that you do not need to specialize in the procurement of Surge for the Sensor line. Suppressor.

- Interface integration and simplification for installation integration considerations

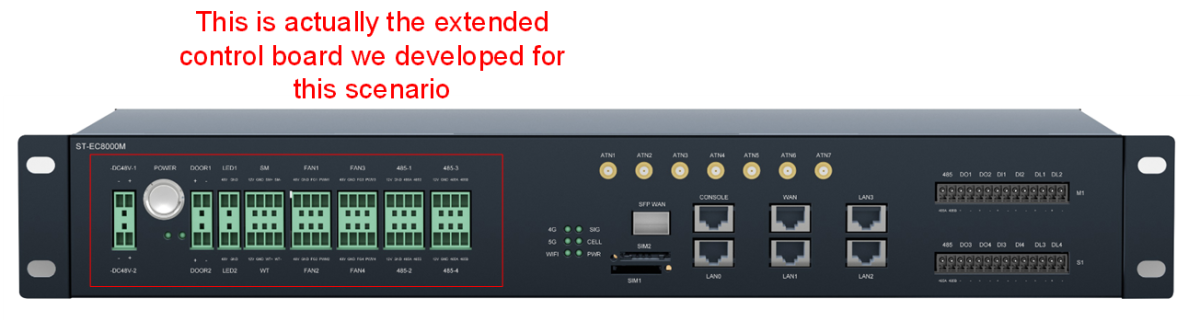

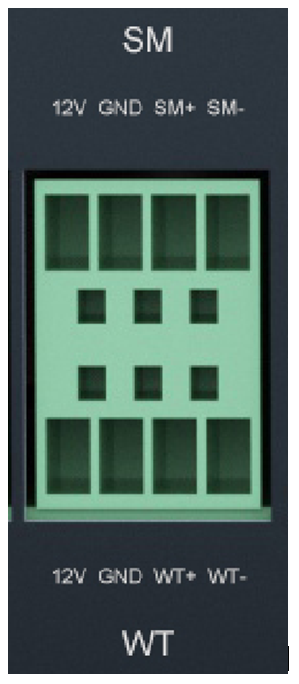

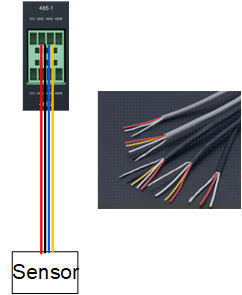

The most important aspect of the extended control board is to help simplify the power and signal interfaces to the sensor. Let’s look at the following example

The system pictured above was designed for a Telecom scenario. On the left in this section is actually a control board. let’s compare it with the 485 interface.

We need to consider the power cable to the sensor and the signal cable to the sensor. Between them we need to consider the surge suppressor connection. This is actually a bit tricky when you have a lot of sensors, and it’s easy to get it wrong.

We generally specialize in the design of the control board, the 485 interface, for example, we will generally be designed as a 4-pin interface, the interface contains DC12V power supply and 485 signals. The advantage of this is that customers do not need to distinguish between the power supply and signal, only need to use this interface can be. Then we provide customized cable based on this interface, this cable has 4 cores including DC12V and 485, so that it is only one cable for customer installation. So when we have three sensors, that’s three cables. The amount of cables is greatly reduced, and the complexity of installation is greatly reduced.

For example, we have water leakage sensor and smoke sensor, they are usually powered by DC12V, and the signal is based on dry contact signal. Then we will design a special interface for it during the design time. This will be very convenient when installing.

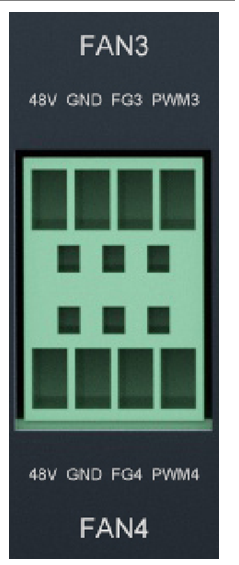

This is a 48V fan interface, you can know the fan speed by FG, and you can control the fan speed by PWM4. We will also specialize it into one interface. It will be easy to install.

Then 485 modbus, 4-20ma, etc. who have the same principle.

We can customize these cables for you to make your frontline deployment easier. Of course, you can also make your own locally, as the interfaces are simpler and easier to work with.

5. Summary

There are many ways to optimize Connect IoT Sensor to IoT Gateway. The general idea is to separate the customized part from the standardized part. Don’t try to cover all scenarios with one standard product. This is not realistic. The end result is that customers have to bear a lot of trouble for on-site deployment.